|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Understanding CRM for Manufacturers: A Comprehensive ExplorationIn the ever-evolving landscape of manufacturing, businesses are increasingly turning to Customer Relationship Management (CRM) systems as a pivotal tool for enhancing operational efficiency and customer satisfaction. At its core, CRM for manufacturers serves not only as a repository for customer data but as a strategic asset that drives growth, fosters stronger relationships, and streamlines processes. So, what exactly makes CRM an indispensable ally for manufacturers? To begin with, the integration of CRM systems in manufacturing environments is primarily about enhancing visibility across various touchpoints. This visibility translates into better forecasting, more effective demand planning, and ultimately, the ability to deliver products that meet or exceed customer expectations. With a CRM, manufacturers can track customer interactions in real-time, allowing for a nuanced understanding of client needs and preferences. This, in turn, informs product development and helps tailor marketing efforts, ensuring they are both relevant and impactful. Moreover, CRM systems are instrumental in breaking down silos within manufacturing organizations. By fostering a more collaborative environment, these systems enable different departments-from sales and marketing to production and logistics-to work seamlessly towards common goals. This synergy not only boosts productivity but also reduces the likelihood of errors that could result in costly delays or rework.

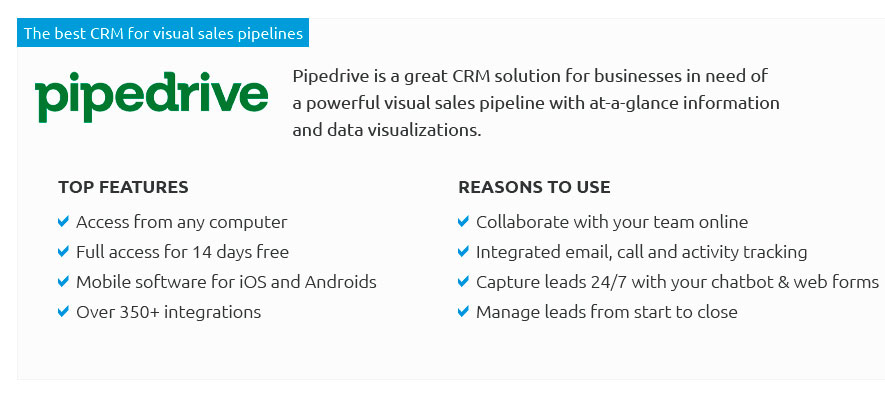

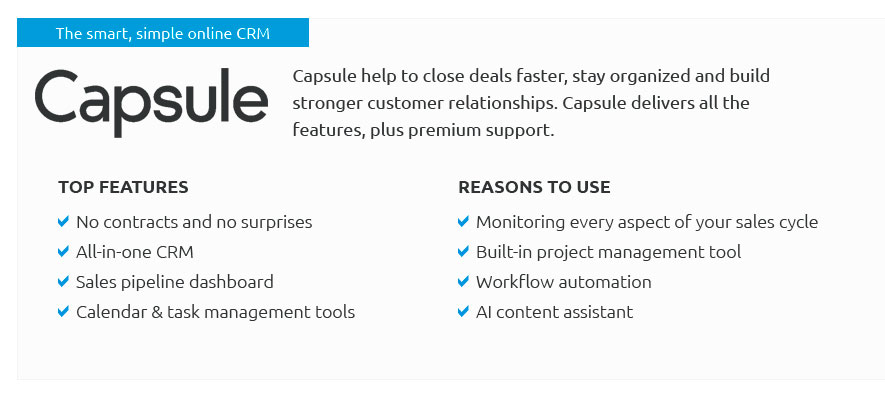

However, it is essential to recognize that not all CRM solutions are created equal, especially when it comes to manufacturing. Choosing the right CRM requires a careful assessment of specific business needs and challenges. Factors such as scalability, integration capabilities, user-friendliness, and industry-specific features should weigh heavily in the decision-making process. An ideal CRM for manufacturers should offer robust support for supply chain management and inventory control, two critical components that are often the backbone of manufacturing operations. In conclusion, while the implementation of a CRM system represents a significant investment, the potential returns in terms of increased efficiency, improved customer satisfaction, and enhanced profitability make it a worthwhile consideration for any forward-thinking manufacturing business. As technology continues to advance, the role of CRM in manufacturing will only grow in importance, underscoring its status as an essential tool for navigating the complexities of modern manufacturing landscapes. https://www.webfx.com/industries/industrial/manufacturing/crm/

CRM for manufacturing is software that helps your industrial company manage relationships with prospects and current clients. It stores and tracks customer and ... https://www.reddit.com/r/CRM/comments/1bcaa03/manufacturing_agency_looking_for_a_crm/

Working at a Manufacturing agency. We've been using OnePageCRM mostly without issue but we've hit our storage cap in about 5 years of use. https://www.creatio.com/industries/manufacturing

Easily manage your contacts and accounts via a single database and enjoy a 360-degree view into your customers' and partners' profiles, history, and engagement ...

|